Are you a member looking to learn the basics of railway modelling? Why not come along on a Tuesday evening and join the Starter Layout group? The group meets at 7:30pm in Dean Hall (12:00 if there is a committee meeting in the evening). If you are not a member yet then please visit our Membership page for info on how to join the MMRS.

The intention to build a “starter” layout, to encourage members wishing to develop construction skills, with the assistance of some of our experienced modellers, was announced at the 2023 Exhibition as part of our recruitment drive.

The intention to build a “starter” layout, to encourage members wishing to develop construction skills, with the assistance of some of our experienced modellers, was announced at the 2023 Exhibition as part of our recruitment drive.

At the initial meeting on Tuesday 9th April 2024 the proposed layout was discussed and the general design of the layout and baseboards was agreed.

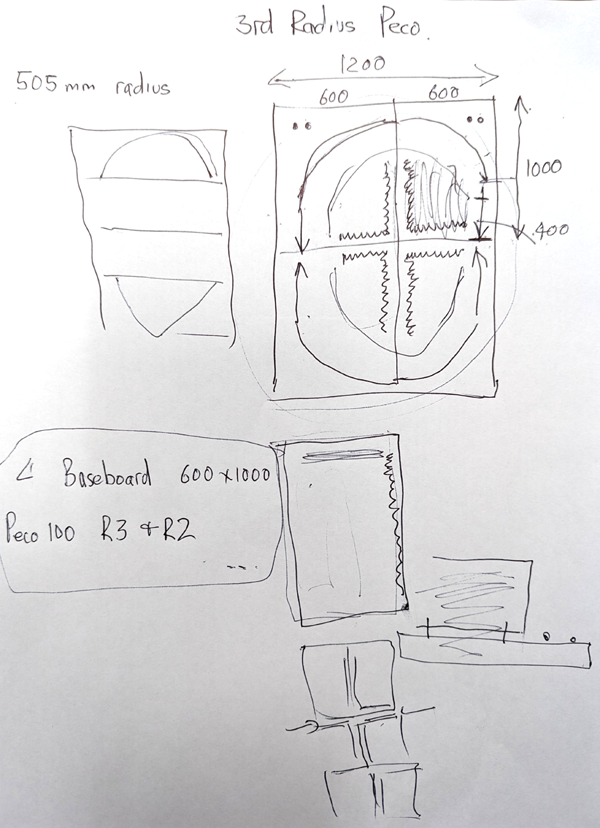

It will initially consist of four 600mm by 1000mm baseboards with backscene uprights, These can be formed into a larger layout 1200mm by 2000mm as shown in the associated sketch. Each “quarter” can be worked on independently and may represent completely different scenes; summer/winter, town/countryside, seaside/mountains.

The boards have been ordered and the track (Peco Setrack) will purchased in the next couple of days.

The Starter Layout group will meet on Tuesday evenings (Tuesday afternoon when there is a committee meeting). Anyone is welcome no matter what skill level they have. This is a layout for starters and learners and will provide the opportunity to sharing skills and mutual improvement.

A quick update on the starter layout group (April 2024)

Our first discussion was all about what size and type of boards to use. Bearing in mind this layout will never be completed, will constantly change and is not for exhibiting but for practice and fun. We decided on modular 600mm x 1000mm four boards initially that can be stored in twos back to back. The track to be a simple roundy roundy consisting of two tracks that can be independently wired so allowing both DC and DCC to run.

Our first discussion was all about what size and type of boards to use. Bearing in mind this layout will never be completed, will constantly change and is not for exhibiting but for practice and fun. We decided on modular 600mm x 1000mm four boards initially that can be stored in twos back to back. The track to be a simple roundy roundy consisting of two tracks that can be independently wired so allowing both DC and DCC to run.

We have been practicing our soldering skills, with regard to drop wires from the track. Our experts helped with the techniques, different areas where the wires could be attached to the track namely directly underneath, along the side of the track and on the fishplates. We still need more practice; I expect soldering will always be turning up as a topic/practice table top exercise. A couple of us will be on the soldering course to improve further.

The use of a multimeter was also demonstrated on some point motors (kindly donated by an mmrs member), the diode, resistance and voltage settings talked over. Again this was overseen by one of the ‘experts’ who turned out to help.

The alignment of the boards was talked about and again one of the experts brought in his boards for the 100year layout challenge showing the space saving storage we are adopting for our boards and that we might consider the use of magnets both as assisting in alignment, locating scenic items and in their electrical capabilities.

The alignment of the boards was talked about and again one of the experts brought in his boards for the 100year layout challenge showing the space saving storage we are adopting for our boards and that we might consider the use of magnets both as assisting in alignment, locating scenic items and in their electrical capabilities.

It was nice to see one starter helping to fix another starters loco without any help, then testing it with a 9volt battery and when placed on some old track we could demonstrate the effect of dirty track on running performance.

We are expecting our boards any day now so why not pop in and help us assemble them?

Starter Layout 2

The Group now has an official budget to get it off the ground after the committee approved our estimated submissions.

A few weeks passed whilst we awaited the baseboards but the starters were not idle and, thanks to one of our starters, we were shown a very cheap way of producing scenic landscapes to practice on. It simply involves cardboard, cereal packets, newspaper and PVA Glue to bind it all together. Once the PVA has set, you can add papier-mâché details then you are ready to practice static grassing, bushes, fencing etc, building up an appealing piece of scenery you may wish to use. From the pictures I hope you can see the cardboard main structure. This is followed with a woven lattice of

cereal box strips giving a good surface for the newspaper strips, which can be painted when dry. Surface contours can be added later, again using papier-mâché

Now that the first four boards have arrived, we are about to tackle their assembly and the experts explained how to go about putting them together, so as to do a good job – after all they are going to be well- used and manipulated by the starters now and in the future. Firstly we checked and identified the parts with which our experts were familiar and next came the dry assembly which some of us dived straight into while others correctly read the instructions!

Now that the first four boards have arrived, we are about to tackle their assembly and the experts explained how to go about putting them together, so as to do a good job – after all they are going to be well- used and manipulated by the starters now and in the future. Firstly we checked and identified the parts with which our experts were familiar and next came the dry assembly which some of us dived straight into while others correctly read the instructions!

Once we were happy with the dry assembly the parts were glued and pinned together. Clamps and masking tape was used to hold the two units together as the PVA glue dried. Thought had to go into the ends of the boards as the hand of the board has to be considered for the final assembly.

Once we were happy with the dry assembly the parts were glued and pinned together. Clamps and masking tape was used to hold the two units together as the PVA glue dried. Thought had to go into the ends of the boards as the hand of the board has to be considered for the final assembly.

At the end of the session we were well on the way to completing two boards.

More experts are stepping forward to help with future developments – especially in electrical fields. We are going to get help with servo control and our DCC controller may well be assembled by our starters under watchful guidance.

More experts are stepping forward to help with future developments – especially in electrical fields. We are going to get help with servo control and our DCC controller may well be assembled by our starters under watchful guidance.

Why not come along and join us?